Introduction

Battery-powered yard tools are taking over, but it’s not quite the end for gasoline and small engines. You can keep yours running smoothly for years with regular maintenance and some inside knowledge.

I talked with Dave Cheney of DC Carb and learned gallons of tips on small engine maintenance. Plus, he showed us how to rebuild a carburetor, which is not as scary at it sounds.

Meet the Expert

Specializing in carburetor rebuilds, Dave Cheney has been wrenching on small engines for more than 30 years.

Keep your small engines healthy

Feed your machine fresh air

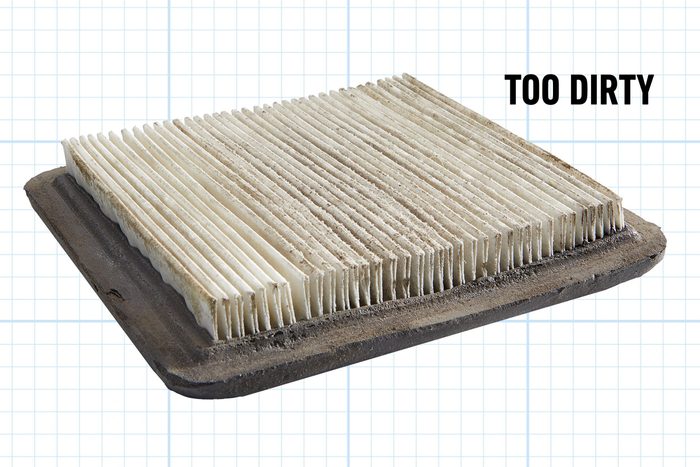

- Small engines need clean air. A clean air filter allows maximum airflow and the optimum fuel/air mixture. You can and should clean the air filter.

- If the air filter is too far gone, or if it’s made of paper and it’s clogged, it needs to be replaced.

Always use new gas

- Small engines love fresh fuel. If your can of gasoline has been sitting around for more than four months, recycle that old gas.

- Ethanol blends have an even shorter life. Through oxidation and evaporation, gasoline becomes less combustible. That leads to poor performance, rough idling and varnish deposits.

- Pro tip: Never add fuel stabilizer to old gas; stabilizer won’t bring gas back to life. Add stabilizer only to fresh gas to extend its use.

Avoid ethanol blends

- Small engines prefer ethanol-free gas.

- Ethanol attracts moisture from the air, which separates from the gas and sinks to the bottom of the tank. This can cause ignition problems.

- But that’s not the worst of it. Ethanol is also corrosive and burns really hot, which can cause overheating and severe engine damage.

Check for spark

- A spark plug checker can provide critical information.

- First, it will tell you if electricity is getting to the spark plug.

- Second, if there is no spark, it lets you determine the cause of failure.

Inspect the spark plug diode

1. Clean and reuse

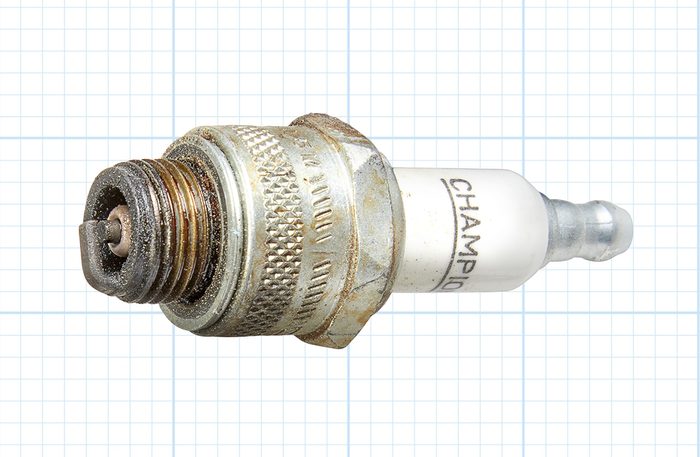

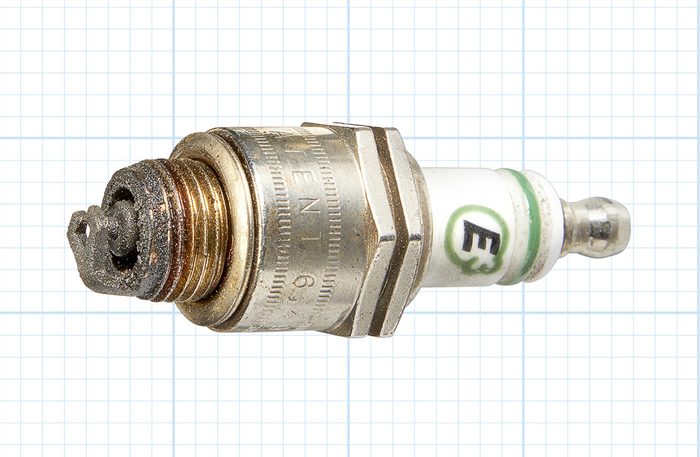

- If the spark plug looks slightly brown — not too dark — simply clean the spark plug with a soft wire brush, check the gap and reinstall.

2. Replace

- Once your spark plug becomes an oil-fouled and deteriorated electrode, it needs to be replaced.

- A new spark plug costs less than $10. It will create the right spark to best ignite the fuel/air mix in the combustion chamber.

Carburetor too far gone? Buy new!

- If your carburetor has reached the point of no return, finding a new replacement online is easy.

- Cheney says Amazon and eBay are great places to start looking.

Clean/Re-build the Carburetor

We’ve all done it — delayed fall maintenance until spring. The engine might fire up but it won’t stay running for long. It’s time to disassemble and clean the carburetor.

1. Remove the carburetor

- Disconnect the fuel line. If there’s still fuel in the tank, crimp the line to avoid leaks.

- Most of the time you’ll find two bolts holding the carburetor to the engine. Remove these bolts and the carburetor.

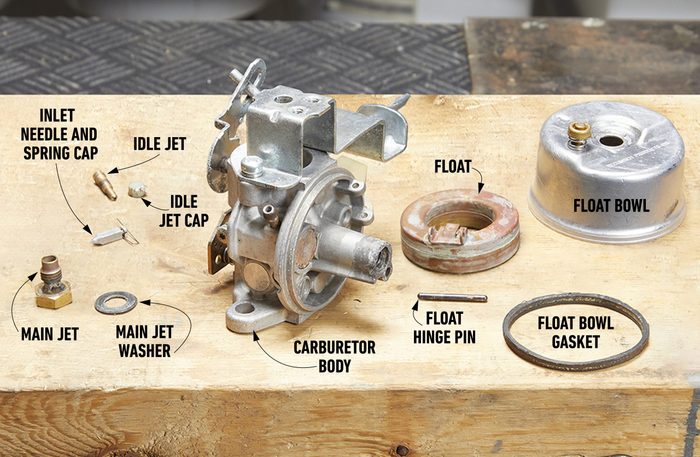

2. Disassembly

- After removing the main jet and the float bowl, Cheney pokes out the float hinge pin with a nail set.

- Take the float off with care. The inlet needle and spring clip are under the float and easy to lose.

3. Remove the idle jet

- A dirty idle jet is the reason small engines pulse and surge instead of idling smoothly. It’s also easy to overlook.

- On this carburetor, the idle jet is behind a small plastic cap.

- Cheney uses an old dental pick to pop out the cap. Then he removes the idle jet with a small flat-head screwdriver.

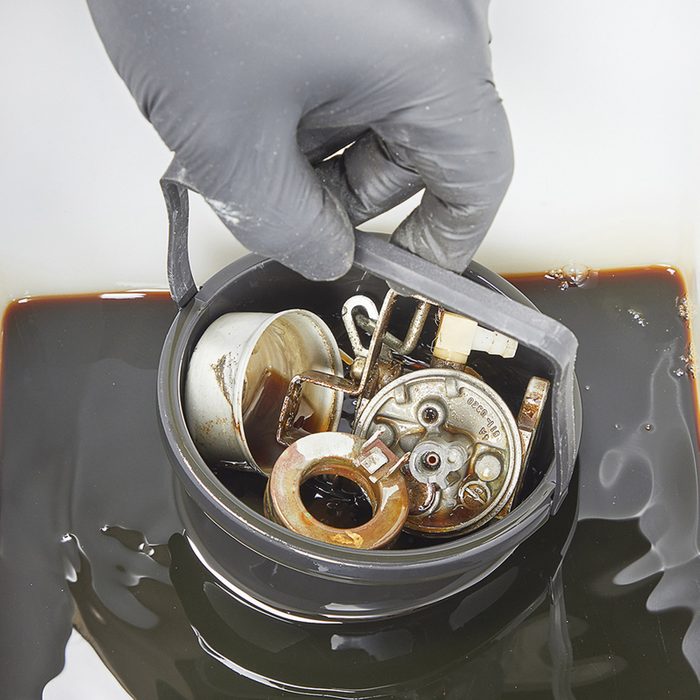

4. Soak in carb cleaner

- Soak the parts in Berryman Chem-Dip cleaner for 15 minutes. This takes care of most surface grime.

- After soaking, use a brush to clean off any remaining debris.

5. Deep cleaning

- A deep clean removes debris not reachable by soaking.

- Cheney uses an ultrasonic cleaner, but you can place parts in a pot of boiling water for 15 minutes.

6. Clean the needle seat

- To make sure the needle seats cleanly, clear debris out of the needle seat with a cotton swab.

7. Reassemble and install

- Lay the clean parts out on your bench and do one final inspection.

- Reassemble the carburetor, bolt it to your machine and don’t forget to prime it!

Rules for seasonal storage

Drain the carburetor

- You need to take one more important step after running your small engine out of fuel for the season.

- Some gas will remain in the carburetor’s float bowl, and you need to drain it completely. Many carburetors have a small drain plug on the bottom of the float bowl for this purpose.

- If left to sit, the gas will varnish and you’ll need to remove the carburetor to clean it.

Don’t winterize — exercise

- Perhaps the easiest way to avoid the downside of seasonal maintenance tasks is to “exercise” your engine.

- Instead of draining the engine of all gas, keep the fuel tank full in the off-season and run the engine once a month for about 10 minutes. Cheney has used this technique for years. It saves him time and provides peace of mind.

- He knows his small engines always have good gas and the internal workings are always coated in fresh oil. Seems like a no-brainer.

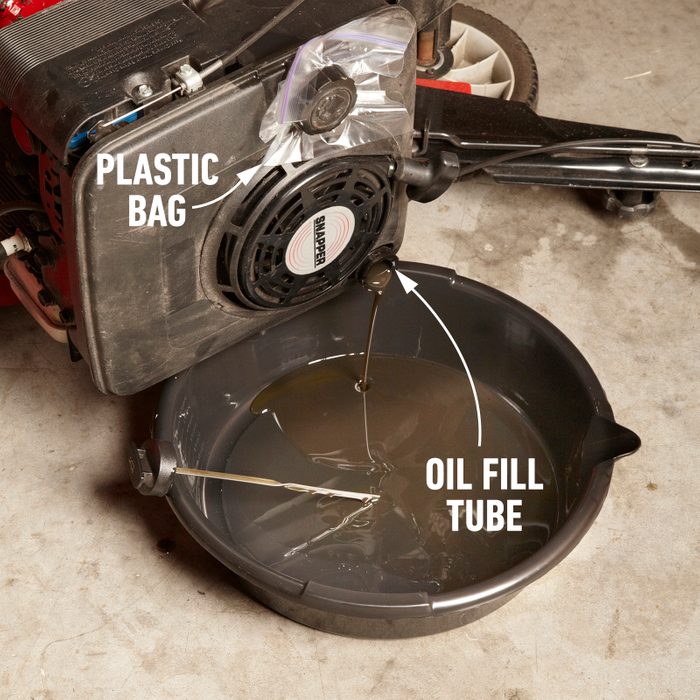

Change the oil

- Change the oil in your small engine every season.

- Fresh, clean oil keeps sludge from building up and helps maintain good compression.

- Pro tip: Some lawn mowers don’t have an oil drain plug; the oil drains out of the fill tube at the top of the engine. Before you tip over your lawn mower to drain the oil, unscrew the gas cap and stretch plastic over the gas tank opening. Then screw the cap back on. The plastic will prevent gas from leaking out the cap vent.

Dave’s Bench Kit

Cheney depends on these tools the most in his shop.

Screwdrivers

- Basic? Yes. Indispensable? Yes, also that.

Flexible pry bar

- This strong, non-marring poly/nylon pry bar won’t damage brass or aluminum. Get a set for $10 at Harbor Freight.

Wrench

- Cheney has a set of combination wrenches in imperial and metric.

Needle-nose pliers

- You’ll always need a pair when working on carburetors.

Ratchet driver

- This 1/4-in.-drive ratchet with an extension gets the socket into tight places.

Dental pick

- An old dental pick can poke, pull and clean where other tools can’t.

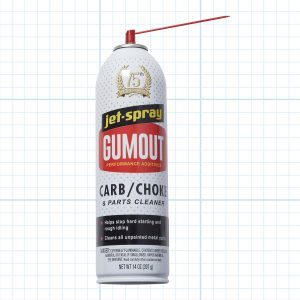

Carb cleaner

- Gumout carb cleaner is available at all auto parts stores.

Slip joint pliers

- These adjustable pliers can play many roles.

Hose clamp pliers

- Removal of flat-type or ring-type hose clamps is much easier with these ($14 online).

Hose pinch

- These locking pliers will clamp on a hose without causing damage ($25 online).

Wire cutters

- Cheney uses these for snipping linkages.

Nitrile gloves

- Cheney prefers these tough, black nitrile gloves.

Wire brush

- A must-have for cleaning small parts.

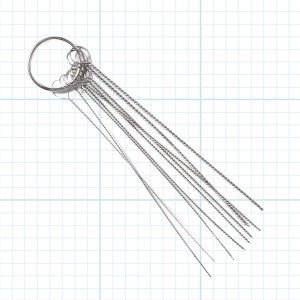

Jet cleaning brushes

- These micro-wire brushes remove debris from jets.

Article source here: Small Engine Maintenance Tips from the Pros

No comments:

Post a Comment