Introduction to Saw Blades

Saw blades seldom get the attention they deserve. You might purchase them based on price, or grab what’s on the shelf in the correct size, and think it’ll be OK. It probably will be … just OK. The right saw blade will produce cleaner and more accurate cuts, and do it safely. That means better DIY results the first time.

Here’s what you need to know about blades for table, miter and circular saws.

Blades For Table Saws

Thin-kerf vs. standard kerf

Which type should you buy? That’s determined by the power of your saw.

Personally, I use a thin-kerf blade for any table saw under three horsepower (hp), which includes all portable jobsite saws. A thin-kerf blade is 25 percent thinner than standard kerf, therefore it has 25 percent less cutting resistance. With a thin-kerf blade installed, your jobsite saw will feel like a powerhouse.

This is the blade you need

A combination blade for the table saw is perfect for the casual user. It produces clean crosscuts in solid wood or plywood, and rips plywood with acceptable results. Most combo blades expose their weakness when ripping thick lumber; the gullets are too small to effectively eject chips and keep the blade cool.

These are the blades you want

Plywood/melamine blade

With a less aggressive rake angle and a steeper top bevel, these blades minimize chip-out in manufactured sheet material.

Ripping blade

A proper ripping blade can do more than produce glue-ready straight cuts along the grain. A ripping blade with flat teeth will produce a true flat-bottom kerf, perfect for joinery cuts such as dadoes, rabbets and tenons.

Crosscut blade

With teeth that cleanly sever wood fibers, this blade will give you glass-smooth cuts across the grain.

Blades For Stationary Crosscut Machines

Tooth count matters

A 10-inch finish saw blade has 60 to 80 teeth. That tooth count produces beautiful cuts.

I always use a high-tooth-count blade in stock that’s 1/4-in. or thinner, and a lower-tooth-count blade for thicker stock.

Negative hook angle

In miter saws, especially sliders, use a blade with a negative hook angle. The tips of the teeth lean backward in relation to the material. This design greatly reduces the risk of kickback and produces less chip-out as the blade exits the wood.

In contrast, a positive hook angle can grab and lift the workpiece, giving you fuzzy cuts. Not safe, not good!

Use full-kerf blades

Miter saws, especially sliding miter saws, may subject the blade to higher torsional stress. That’s why I always use a full-kerf blade on my sliding miter saw. With a stiffer body and larger teeth, this blade will resist flexing and give you a clean, accurate cut.

Blades For Circular Saws

Carbide-tipped circular saw blades

When I first used my father’s circular saw, the cheap stamped steel blade smoked, burned and disappointed. Blades like this are still made for some reason. You can spot them easily, but don’t ever use them. A high-quality carbide-tipped circular saw blade cuts cleaner, won’t burn your wood, and costs only about $15.

Small saw, big choices

Improve your circular saw game with a range of job-specific saw blades. For less than $100, expand the usefulness of this saw with dedicated blades for demolition, solid lumber, plywood even cement composites. You’ll make better cuts and your saw will last longer.

Saw Blade Pro Tips

Saw blades for cutting metal

Don’t cut metal with that nice crosscut blade! It might cut, but metal will damage the teeth.

Blades for cutting nonferrous metals feature a negative hook angle, and the tips of the teeth don’t flare out to the sides. Before cutting metal, invest in a blade made for that purpose and save your wood blade for wood.

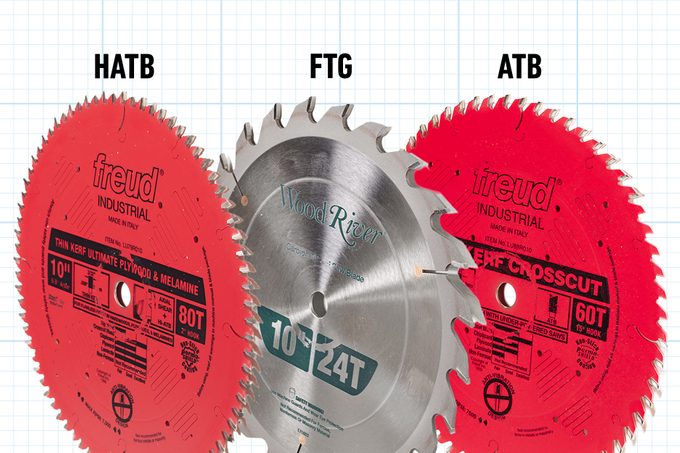

Acronyms for the most common tooth grinds

- FTG: Flat Top Grind, most often found on ripping blades.

- ATB: Alternate Top Bevel, most common on crosscut blades.

- HATB: High Alternate Top Bevel. Plywood and melamine blades use this tooth geometry to minimize fuzzy edges.

- TCG: Triple Chip Grind. Found on metal-cutting blades and some ripping blades.

- ATB-R: Alternate Top Bevel with Raker. Found on combination blades for the table saw.

Cleaning saw blades

Your blade isn’t dull, it’s dirty! And if you keep cutting with a dirty blade, it’s going to get dull — fast! Cleaning the teeth regularly will keep the blade sharper longer.

Pro tip: Make a habit of cleaning your saw blades immediately after use. You can easily remove any pitch buildup. Then the next time you reach for that blade, it will be ready to go.

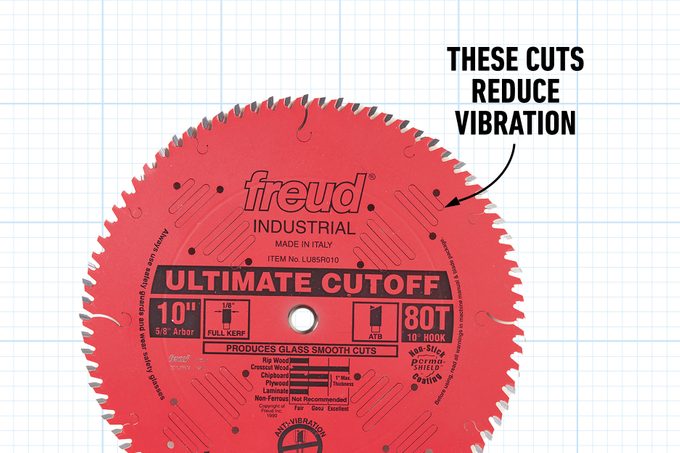

Saw blade vibration-dampening slots

There’s more to a saw blade than its teeth. I prefer laser-cut blades with vibration-dampening slots cut into the blade body. Blades with these slots cut cleaner and quieter. Blades without vibration-dampening slots vibrate freely. This makes your blade ring like a bell which makes your saw loud!

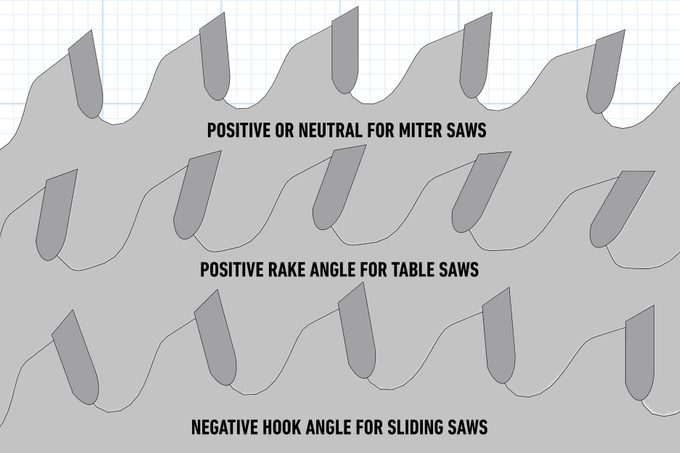

Hook angle explained

Positive rake angle for table saws

Positive rake angle on the table saw not only produces a better cut, but is safer, too.

Positive or neutral for miter saws

Stationary miter saws can safely accept any hook angle. The blade is not moving in relation to the work, so the material being cut dictates the rake angle.

Negative hook angle for sliding saws

Taking the crosscut blade off your table saw and putting it on the sliding miter saw could have dangerous consequences. Have you ever had a piece of wood jump out of your hands on a sliding miter saw? It might be because you’re using the wrong blade.

Sliding miter saws and radial arm saws require a blade with negative hook angle. As the blade spins, the teeth will push the part down and into the fence rather than catching it and pulling it up.

Shopping for saw blades

Home centers stock many mid-level construction blades. If you’re looking for a high-end woodworking blade, find your way to a specialty woodworking store like Rockler or Woodcraft. Their experts will help you find what you’re looking for.

Meet the Expert

Article source here: What To Know About Saw Blades

No comments:

Post a Comment