Weather stripping on our cars is an unsung hero. We rarely notice it, but if we didn’t have it, driving around would be a noisy, wet and miserable experience.

“Weather stripping, like the spare tire, or sway bar links, are totally ignored until they go bad or are damaged,” says master technician, author and instructor Bob Lacivita. “But they are important to your driving experience, comfort and health.”

Weather strip on cars (aka gasket) is apt to get damaged if it freezes to the door frame or glass, then tears when you open the door or trunk. Ultraviolet rays from the sun can also break down, or dry rot, the rubber, causing it to leak, lose shape or get folded.

“Although weather stripping is resilient, normal wear and tear, such as dragging your feet getting into and out of your car, or moving items in and out of the trunk, can quickly damage the rubber seal,” says Lacivita.

If that happens, it’s usually a DIY job, but you might want to call a pro if:

- It’s glued in (vs. held in with clips, channel or friction), in which case cleaning the channel the stripping sits in can be frustrating and time-consuming;

- There is tricky interior trim to take off, which you’re worried about breaking;

- The strip being replaced is specific to your vehicle, and the part is difficult to locate.

What Is Car Weather Stripping and What Does It Do?

Car weather stripping is the rubbery lining that seals the gaps between the vehicle body and the doors, windows, trunk, hood and windshield. Weather stripping on a car serves various purposes:

- Keeps out rain, snow, air and critters

- Helps prevent interior mold and mildew

- Helps maintain air quality

- Insulates passengers from hot and cold outside temperatures

- Protects vehicle from damage

- Enhances driving comfort

- Maintains vehicle appearance and resale value

“To test weather stripping fit, place a dollar bill between the weather strip and the part being sealed,” says Lacivita. “Feeling resistance when pulling the bill out signifies a good seal.”

If you suspect you have a weather stripping issue, here’s how to repair, replace and maintain weather stripping on a car.

When to Replace Weather Stripping

If you see dry rot or chunks missing, it’s time to replace your weather stripping. Also, if you have wind noise or water leaking near the door frames, check them for damage.

“It does get damaged by dry rot, or exposure to the heat of the sun and the cold of the winter,” says Thomas Patterson, Director of New Product Development and Technical Training at Glass Doctor. “Expanding and contracting causes fatigue in the EPDM [rubber] and causes it to loosen.”

How to Repair Weather Stripping on a Car

Tools

- Flathead screwdriver

- 90-degree picks (to clean out channel retainer tracks)

- Sandpaper

- Clean, dust free rags

- Microfiber towels

- Utility knife (optional)

Materials

- Replacement weather stripping

- Adhesive remover

- Weather strip adhesive

- Silicone spray

- Silicone gel (optional)

- Low adhesion paper tape or clamps (optional)

- Foam backer rod (optional, for repairs)

Time: 20 minutes to several hours

Cost: varies

Complexity: beginner

Step 1: Assess the damage

If you only have small tears or cuts, you can probably patch those with weather strip adhesive (be careful, it’s really sticky). Make sure to promptly wipe off any excess glue using a cloth and solvent-based liquid cleaner.

Similarly, if your weather strip is just falling or popping out a little, use a few drops of weather strip adhesive to hold it in place.

If your weather strip has lost shape or gotten folded over, you may also be able to repair it by cutting a small opening with a utility knife and inserting a piece of foam backer rod (lubricate it with silicone first). Use a metal rod or coat hanger to push it in.

Step 2: Remove the old strip

If you can’t repair your weather stripping, you’ll need to replace it.

- Gently peel the old weather stripping from the door or opening.

- Be careful to avoid damaging the paint.

Step 3: Clean the area

- Spray the area where the old weather stripping was with an adhesive remover.

- Use the cloth and picks to wipe away adhesive residue and other debris. “The channel or mounting surface must be absolutely spotless of any glue, residue or old weather stripping,” says Lacivita.

- Let all areas dry completely.

Step 4: Apply new adhesive

- Test (or dry fit) the weather stripping to ensure it fits into the area and matches the original strip’s size and shape. If it doesn’t, trim it accordingly.

- If your new weather stripping doesn’t come with a pre-coated adhesive attached, apply a thin and even strip of adhesive to the vehicle surface where the new strip will be attached.

- Adhere to any manufacturer instructions for adhesive application and drying recommendations.

Pro-tip: “I recommend 3M Black Weatherstrip Adhesive,” says Lacivita. “I am not a fan of 3M Yellow Weather Strip adhesive. Once it fully cures, it’s worse than contact cement to remove.”

Step 5: Install the weather stripping.

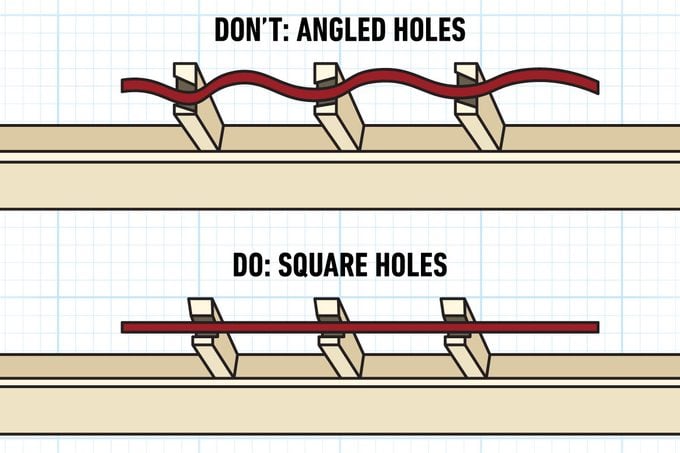

- Carefully position the new weather stripping onto the adhesive.

- Press it firmly in place.

- Use tape or clamps to hold the strip in place until the adhesive dries. If you’re not using low-adhesion tape, apply a little silicone underneath so it doesn’t rip out the new weather stripping when you go to remove it.

“It’s vital to allow the adhesive to cure and bond to the surface of the door!” says Patterson. “During this time, do not close the door before it’s done curing as it can cause the strip to shift.”

Step 6: Test and clean up.

- When the adhesive is set up, test it by gently opening and closing the door.

- Inspect for gaps in the adhesion.

- Use a clean cloth to remove excess adhesive.

How to Maintain Car Weather Stripping

Maintaining weather stripping on a car will help keep it soft and flexible. From time to time, or when you find dust and debris on the weather stripping:

- Use car wash soap and soft brush to clean it especially the back side of weather stripping where dirt, grit and debris easily can build up plus any vehicle doors or other parts that come into contact with it.

- Dry it completely using a microfiber towel.

- Apply silicone-based rubber protectant or silicone paste (use paste sparingly), until the rubber looks slightly wet. Lacivita recommends using a spray-pump protectant vs. an aerosol-based one because some propellants in aerosols can harm rubber.

- Apply a second coat of protectant, if the weather stripping is old and dry.

“A good coating of any silicone-based protectant can always extend the life of the weatherstrip,” says Patterson. “When detailing the inside of the car, use the same protectant on the seals you used on the leather or vinyl trim.”

How Much Does It Cost to Replace Weather Stripping?

It depends. A roll of generic self-stick or friction weather stripping costs less than $25. “On the other hand, a vehicle-specific weather strip that requires removing trim, or removing the sunroof, can run up to $800,” Lacivita says.

FAQs

Can you drive without weather stripping?

Yes, but why? says Lacivita. “Besides being open to the elements and annoyed with road noise and parts slamming into each other, driving without weather stripping would be uncomfortable since the HVAC system has to work harder to compensate for temperature changes.”

How long does weather stripping last?

If cared for properly, it should last the lifetime of your vehicle. “I would highly doubt that any normal vehicle owner will ever need to replace such items on their car,” says Patterson.

How do you know what kind of weather stripping to use for your car?

If your weather stripping is vehicle or part specific, you’ll need to order it from a dealer or an aftermarket supplier. You can also try to carefully remove a small piece to determine what type you need, such as if it fits into a channel, attaches with clips or is glued to the vehicle’s body. If you’re lucky, you can save money by ordering a generic roll.

About the Experts

Bob Lacivita was an award-winning General Motors master technician for 27 years and has been an ASE master technician since 1978. For 25 years, he also worked as an automotive technical educator and administrator. Today he writes about DIY car repairs and vehicle maintenance for Family Handyman, Reader’s Digest and other outlets.

Thomas Patterson is Director of New Product Development and Technical Training at Glass Doctor. He has been in the glass business for 45 years and worked on thousands of vehicles. Glass Doctor is a Neighborly Company, with more than 300 retail locations.

Article source here: A Guide to Repairing and Maintaining Weather Stripping on Your Car