Step 1: Assemble the soldering tools

The recipe for soldering success calls for two parts prep work and one part science. If you do the two critical preparation steps well—joint cleaning and heating—the solder itself will finish the job. When the joint is hot enough, molten solder instantly flows into the joint and covers the entire mating surfaces completely, almost as if following detailed instructions. It hardens there as it cools. Presto, you have a solid, leakfree joint.

In this article, we’ll walk you through the basic steps how to solder copper pipe and soldering copper pipe used in most homes. Learn the different types of copper pipe as you prepare. As you’ll see, you don’t need special skills for soldering copper pipe fittings successfully. You can easily solder a leakfree copper solder joint on the first try—but you can also make mistakes. We’ll show you how to avoid them, as well as alert you to simple, but critical, safety precautions that’ll protect you from burns and keep your home safe from fire.

The basic soldering tool is a propane torch, which consists of a regulator and tip combination that you screw into the top of a small tank. To operate, open the fuel adjustment valve and light the tip. For lighting ease, we recommend the regulator that has a built-in igniter (above left). The gas lights at the push of a button. If you buy the simpler version (above right), buy a striker as well. Squeezing the wire handle produces sparks, which ignite the gas. The striker is simpler and safer than matches.

Also buy either “tinning flux” (Photo 5) or “paste flux.” The flux acid-cleans the copper surface as you heat the joint, enabling the solder to flow evenly. Both types work well. The tinning flux contains a tiny bit of solder, but you have to add more solder anyway.

You can find all the basic soldering copper pipe equipment at full-service hardware stores or home centers—a propane torch, solder, emery cloth (Photo 3) and flux. We also recommend a tube cutter, flame protector cloth (see opening photo) and heavy gloves and eye protection. Wear the gloves and goggles as well as a heavy, long-sleeve shirt and a hat to protect yourself from burns if molten solder drips.

Types of Solder

Buy lead-free solder that’s designed for copper water pipes; you’ll find it in the plumbing section of the store. Solder with lead is still available, but the lead can leach into your water supply, so don’t use it.

Step 2: Cut copper with a tube cutter

Copper is a soft metal that’s easiest to cut with a tube cutter (Photo 1). Buy one that cuts up to 1-in. tubing, the largest size you’re likely to need for most household water supply lines. Cut larger tubing with a hacksaw, but make sure to file off all the burrs left from the saw teeth. Otherwise your joint will leak. Grip the copper tubing firmly in one hand and tuck one end under your knee to keep it from slipping while you tighten and rotate the cutter (Photo 1). Don’t tighten it too fast; you’ll dent the pipe and have to start over.

Step 3: Remove the burrs

The cut may look clean, but remember to remove the small inside burr (Photo 2), a ridge of copper that’s forced inward by the cutting wheel. Otherwise, it’ll impede the flow of water through the pipe.

Step 4: Clean with emery cloth

Then clean the mating areas of the tubing and fittings, even if they look brand-shiny new. Thorough cleaning is the A-1 key to soldering copper pipe success. It ensures a solid, leak proof joint.

Step 5: Clean with a fitting brush

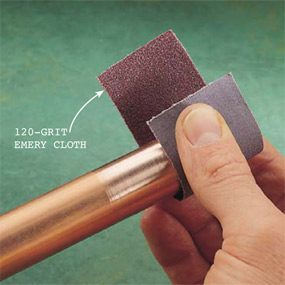

Cleaning is a two-step process—first, clean all corrosion off the mating surfaces (Photos 3 and 4), and second, coat the surfaces with flux (Photo 5), an acidic paste that chemically etches the copper.

Pros clean copper with strips of 120-grit emery cloth, which is usually sold alongside the solder and flux on hardware and home center shelves (Photo 3). But fine steel wool or regular 120-grit sandpaper will do in a pinch. Clean the inside of copper pipe fittings with the emery cloth too; simply roll a short piece around a finger and reach inside. But you’ll soon get sore fingers! The handy fitting brush shown in Photo 4 makes this task easier, especially with small (1/2-in.) copper pipe fittings.

Step 7: Flux the joint

Step 8: Heat the joint

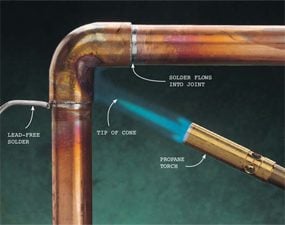

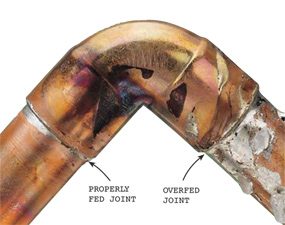

Typically it’s easiest to clean, flux and assemble the entire run of copper and then begin soldering copper pipe joints in place all at once (opening photo). Fire up your torch and adjust the flame so the blue cone in the center is about 1-1/4 in. long. The longer the cone, the hotter the flame. The hottest point is at the tip of the cone, so hold the flame so that the tip just touches the fitting (Photo 6). It’s not necessary to heat the copper tube directly, because the fitting quickly conducts the heat to the tube inside the joint. When the temperature of the copper reaches the solder melting point, the solder wire you’re holding against the copper will suddenly liquefy and flow into the joint. Hold the solder opposite the flame, the coolest point, to make sure all parts of the joint are hot enough. Solder won’t fill spots that are cooler than its melting point. Fill the joint until solder drips out, then move on to the next joint. Give the joint 30 to 45 seconds to cool and harden before putting pressure on it. Be careful; it’ll still be too hot to touch.

Step 9: Use special techniques for tough spots

You can’t solder tubing that has water in it. You have to drain water lines and dry the tubing in the area being soldered. Heating the tube with your torch speeds this up. Make sure any pressure that builds in the tube during soldering can escape. The easiest way is to keep a faucet open at one end of the line.

- If you’re using tubing larger than ¾ in., heat the joints of tubing from several sides to raise the temperature more evenly. Add copper solder from several points and examine the joint to make sure the solder fills the joint on all sides.

- Soldering brass fittings, like the valve in Photo 7, requires more heat. Leave the valve open so pressure doesn’t build inside the tube and cause the joint to leak. And if the valve has soft plastic or rubber parts, remove them if possible to avoid ruining them.

Safety Tips

- Temporarily hang a flame protector cloth (opening photo) or a steel plate over wood and other flammable materials when soldering nearby. In any event, keep a fire extinguisher or bucket of water handy in case you start a fire.

- Shut off your torch when you set it down. The propane tank is tippy. Eventually a lit torch will fall over and burn something.

CAUTION!

Keep a fire extinguisher and a bucket of water or spray bottle handy. . . just in case your torch starts a fire. Remember, your household water supply is often turned off while you work soldering copper pipe!

Required Tools for this Project

Have the necessary tools for this DIY soldering copper pipe project lined up before you start—you’ll save time and frustration.

- Tube cutter

Emery cloth, 120 grit,

Flame protector cloth,

Fire extinguisher,

Fitting brush,

Striker,

Gloves

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials including copper solder ready ahead of time. Here’s a list.

- lead-free

- Paste flux

- Solder

Article source here: How to Sweat Copper Pipe

No comments:

Post a Comment