Click the links below to download the construction drawings and material list for the 2000 shed.

2000 Shed Construction Drawings

Project overview

Even though we’ve engineered this shed to keep complicated figuring and cutting to a minimum, it’s still a big construction project that will take you at least five or six weekends to complete. If you’ve built a deck or similar structure, you’ll have no trouble putting in the foundation and building the walls. To help you through the trickier roof-framing stage, we’ll show you how to make a rafter pattern without using any complex math. You may have to modify our plans slightly to fit your house, but all the basic building techniques we show will be the same.

You won’t need any special tools for this project. You probably already own most of the basic carpentry tools you’ll need to build this shed. Besides hand tools like a hammer, tape measure, square, utility knife, chalk line, sharp chisel, handsaw and a few screwdrivers, you’ll need a 4-ft. level, a line level (Photo 2) and a power drill, plus the bits listed in the story. A circular saw will work for most of the cutting, but the windowsill and drip cap (Fig. C) require bevel cuts that would be easier to make with a table saw. If you don’t own a table saw, ask a woodworker or a full-service lumberyard to cut these pieces for you. A power miter box is another optional tool that would add speed and accuracy to your cutting, especially for finish work. You can rent a power miter box, but for a project this big, I’d recommend buying one.

Step 1: Pick a site and order materials

Scope out the perfect location.

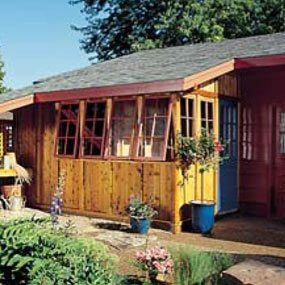

With its simple roof style, this shed can go just about anywhere. Look for a spot on the back of your house where windows and doors aren’t in the way. Behind or to the side of the garage is a good location. We tied our shed roof into the garage roof, but you can also butt the shed roof against a wall, as long as you install metal flashing under the siding and over the shingles where the roof and wall intersect.

In addition, consider: Ground level. The ideal site is flat and sloping slightly away from the house. If the ground slopes steeply, either toward or away from the house, your job will be a lot harder. You’ll have to excavate and build retaining walls or bring in fill. In any case, regrade around the shed to ensure good every drainage and provide a ramp for your lawn mower and wheelbarrow. Roof pitch and headroom. This is the trickiest stage of planning. Our garage has 9-ft. tall walls and a shallow pitched roof. This combination allowed us to continue the roof in a straight line and still have enough headroom at the outside shed wall for standard-height windows and doors. But your house/garage might be different. To ensure adequate outer wall height, stretch a string along the roof and brace a 2×4 temporarily at the location of the outside wall to figure out how much headroom you’ll have (basically the same procedure shown in Photo 9 for making the rafter template). Measure from the string representing the roof down to what will be the top of the 6×6 foundation beam. If this distance isn’t 90-3/4 in., you’ll have to modify the wall height or change the roof slope of our shed plan.

Then call your local building inspections department to find out if your shed location is OK and what’s required to get a building permit. Most cities will accept a plan drawn to scale on 1/4-in. graph paper if it includes all the structural details.

Every region has a few unique building requirements. In cold Northern climates like ours, deep footings are required to prevent frost heaving. In areas with high winds or earthquakes, you’ll need special metal framing anchors to tie everything together. Ask your building inspector what’s required in your area.

Most of the materials for this shed are available at home centers and lumberyards. For a complete shopping list is in the Additional Information below. Here are a few pointers for your shopping trip:

- Pick straight, dry cedar 4x4s. Bowed or twisted lumber will cause trouble when it comes time to install the windows and door. Check at both lumberyards and home centers.

- Make sure the 6x6s are .60 treated, not the less durable .40 that’s sometimes used for landscaping timbers. You’ll probably have to order them.

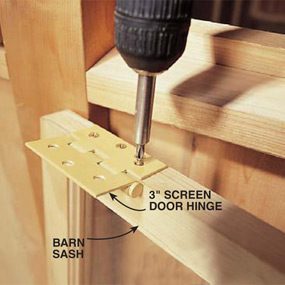

- Barn sashes are sold at some home centers and farm-supply retailers. If you’re willing to modify the plan dimensions, consider using old storm windows in place of the barn sashes. Contractors specializing in window replacements often throw these away.

- Search for an interesting old entry door at salvage yards or architectural antiques dealers, or buy a new one like ours.

Figure A: Framing Details

Note: You can download Figure A and enlarge it from the Additional Information below.

Figure B: Foundation Plan

Note: You can download Figure B and enlarge it from the Additional Information below.

Step 2: Set the foundation

Begin with a square and level foundation.

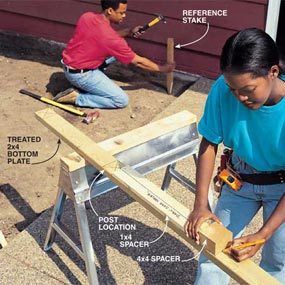

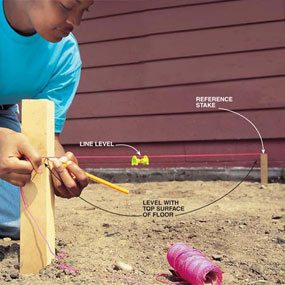

To quickly double-check the dimensions on your plan, mark the post locations on the 2×4 bottom plates and cut the plates to length (Photo 1). Use the dimensions from these plates to set up the batter boards and strings (Photos 2 and 3). It’s best to align the strings with what will be the outside edge of the 6×6 foundation beam. (Remember to deduct 1 in. from the total length of the front wall and 1/2 in. from each side wall so the walls will overhang the beams by 1/2 in. as shown in Fig. C.) We aligned our strings with the inside edge of the 6×6 because the concrete patio was in the way of setting up batter boards. Take your time getting these strings perfectly level and square.

Our shed is held up by 6×6 treated beams bolted to 42-in. deep concrete piers, which are appropriate for the frost depth in our area. Your building inspector will tell you how deep to go in your region. We rested the end of the 6x6s on notches cut into the garage foundation. If you can’t do this, add piers at these locations. About a week before you plan to dig, call the utility companies to locate buried wires or pipes. Use 8-in. dia. cardboard forming tubes for the piers. They allow you to easily establish accurate pier height (Photo 4). Figure one 60-lb. bag of concrete mix for every 1-ft. length of 8-in. dia. tube. After pouring the concrete, position the anchor bolts 2-3/4 in. from the string so they’ll end up in the center of the 6×6 beam.

Tip: Before the concrete hardens, double-check that all the footings are level with each other using a long, straight board with a 4-ft. level on top.

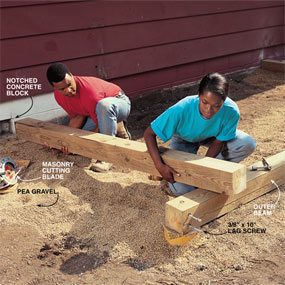

Then let the concrete harden overnight. Before you start on the 6×6 beams, dig out enough soil to allow space for 3 in. of gravel under the beams and 5 in. under the concrete patio block floor for good drainage.

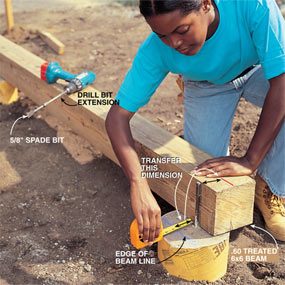

Next, you’ll cut the 6×6 beams to length and bolt them down (Photos 6 and 7). Mark the beam locations on the footings (Photo 5) and cut the 6x6s to align with these marks. Remember to add the amount that will rest on the garage foundation onto the shorter end beams (Photo 7). Paint wood preservative onto the cut ends of the beams before you bolt them down, and countersink the nuts and washers so the walls will slide on easily.

Step 3: Frame the walls and roof

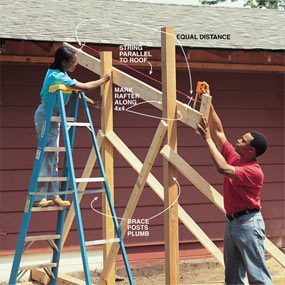

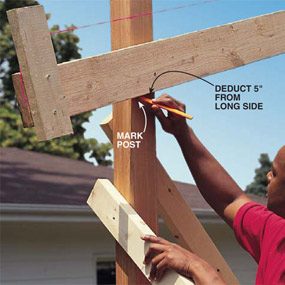

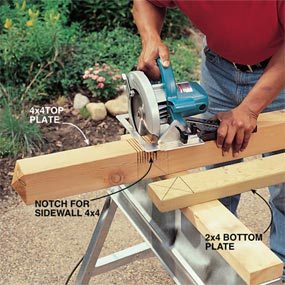

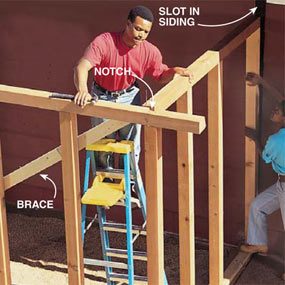

Next, mock up a wall and rafter to make exact patterns rather than using math (Photos 9 and 10). After you’ve marked where the rafter crosses the 4×4 top plate (Photo 10), subtract 5 in. (1-1/2 in. for the 2×4 bottom plate and 3-1/2 in. for the 4×4 top plate) from the high side to arrive at the length of the 4×4 wall posts (Photo 10). Cut all the posts off square at this length. Then assemble the walls and brace them plumb and square (Photos 13 and 14). To tie the side walls to the house, we cut out a slot in the siding and slid the 4×4 wall post against the sheathing. Then, since there were no studs in the existing wall at these locations, we added some from inside the garage to provide solid wood for attaching the walls. After nailing the walls in place, use a handsaw to cut out the bottom plates that run across the door openings.

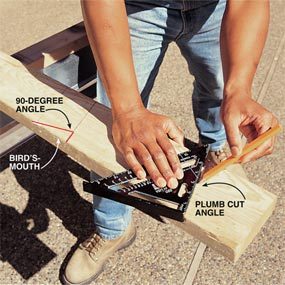

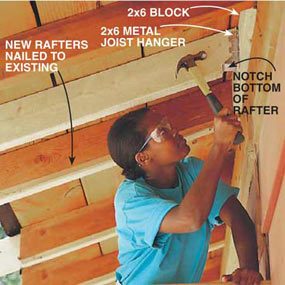

Cut out a rafter pattern (Photo 11) and set it up on the walls to check the fit. This long rafter will need two “bird’s-mouth” cuts, one to fit over the 4×4 top plate of the long front wall and one for the short 4×4 beam that holds up the lattice-covered overhanging section. Adjust the fit as needed and use the pattern to mark the remaining long rafters. Make a second pattern for the shorter rafters.

Sight along the top of the front wall to make sure it’s straight before you secure the rafters.

Figure C: Finish Details

Note: You can download Figure C and enlarge it from the Additional Information below.

Step 4: Finish the roof

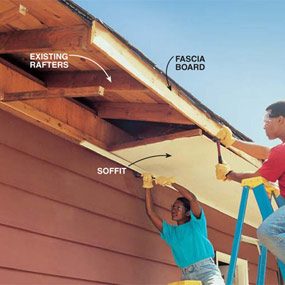

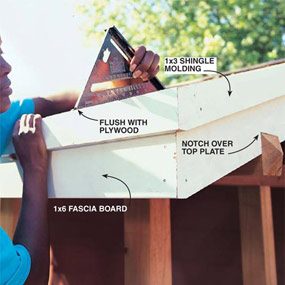

With the rafters in place, nail down the roof plywood (Photo 17) and install the soffit plywood and fascia boards (Photo 18). Match the soffit and fascia details to those on your house.

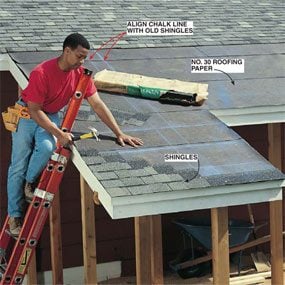

When you cover the roof with roofing paper (Photo 19), tuck the new paper under the existing shingles and paper. Plan the shingle installation and chalk the lines so the old and new shingles line up (Photo 19). Fasten the shingles with 1-in. galvanized roofing nails according to the instructions on the wrapper. When you get to the top, carefully lift the old shingles and remove the first row of roofing nails with a flat pry bar to allow the new shingles to slide underneath.

Step 5: Finish the exterior and floor

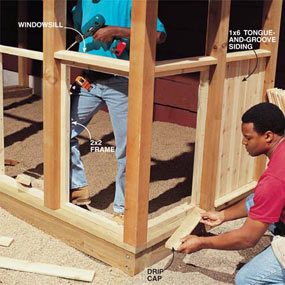

Next, fill in the triangular sections above the wall on each end. Then close in the shed by filling the spaces between the posts (Photo 21). With our shed design, you don’t have to install door and window jambs, but you do have to cut angles on the 3/4-in. x 2-3/4 in. drip cap that fits below the siding, and on the 2×4 windowsill. Use a table saw for these cuts and to rip a 2×4 down to 2-5/8 in. for the pieces above the windows (Fig. C). Photos 21 – 23 show how to install the siding and windows. For our floor we laid 18-in. square concrete patio pavers over a level bed of pea gravel. Cut the pavers along the walls and at the doors with a dry-cut diamond blade mounted in a circular saw. We also used the pavers to build a ramp into the yard from the sliding door.

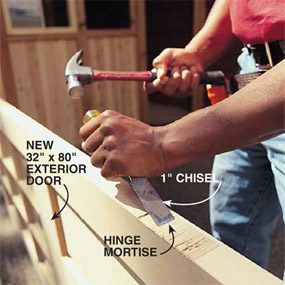

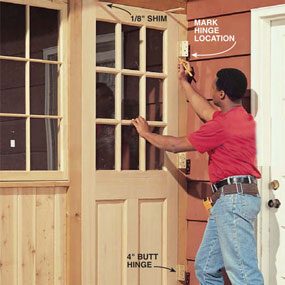

Install the doors after the floor. Photos 24 and 25 show how to hang the entry door. Construct the sliding door by driving 1-1/4 in. galvanized or stainless steel screws through the backside of the 1×6 tongue-and-groove boards into a 1×4 cedar frame. Fig. D and Photo 26 show this detail and how to install the heavy-duty pocket door hardware and three-wheel rollers that suspend the door. Mount a 2×4 open bar holder bracket to the 6×6 to keep the bottom of the door from swinging out. We installed a barn door latch on the outside to secure the door.

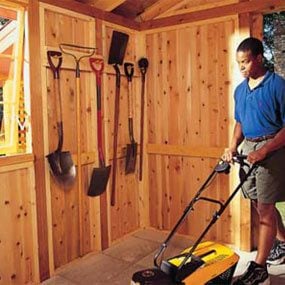

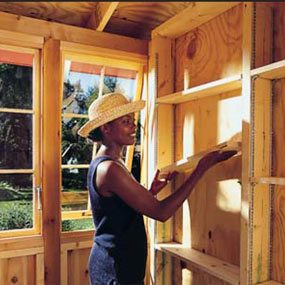

Finally, you can customize the shed for your hobbies. To provide a separate planting area inside the shed, we built a wall of 2x6s spaced 30 in. apart and covered on the back with 1/2-in. plywood. Metal shelf standards and clips support 2×6 shelves for pots and planting supplies. We created a narrow, hollow space next to the windows to allow access to the window latch. Use the lattice-walled overhang to store a gas grill or to hold a potting bench like ours. Or use it as a vine-covered sitting area. Cut the cedar lattice panels to fit between the 4x4s and secure them with 1x2s nailed on each side. Make the bench top by screwing a 2×4 ledge to the 4×4 posts and cutting 2×6 cedar boards to rest on top.

To retain the natural look of your cedar shed, apply two or three coats of a top-quality clear exterior finish. Paint the door and exterior trim with alkyd primer and two coats of top-quality exterior latex paint.

Figure D: Sliding Door Details

Note: You can download Figure D and enlarge it from the Additional Information below.

Additional Information

- Figure A: Framing details

- Figure B: Foundation plan

- Figure C: Finish details

- Figure D: Sliding door details

- Shed shopping list

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Circular saw

- Corded drill

- Drill bit set

- Drill/driver - cordless

- Extension ladder

- Hammer

- Level

- Line level

- Miter saw

- Posthole digger

- Sledgehammer

- Socket/ratchet set

- Speed square

- Stapler

- Stepladder

- Table saw

- Tape measure

- Wheelbarrow

- Wood chisel

Shovel,

String line

Article source here: How to Build a Garden Shed Addition

No comments:

Post a Comment