What To Know Before Buying Circular Saw Blades

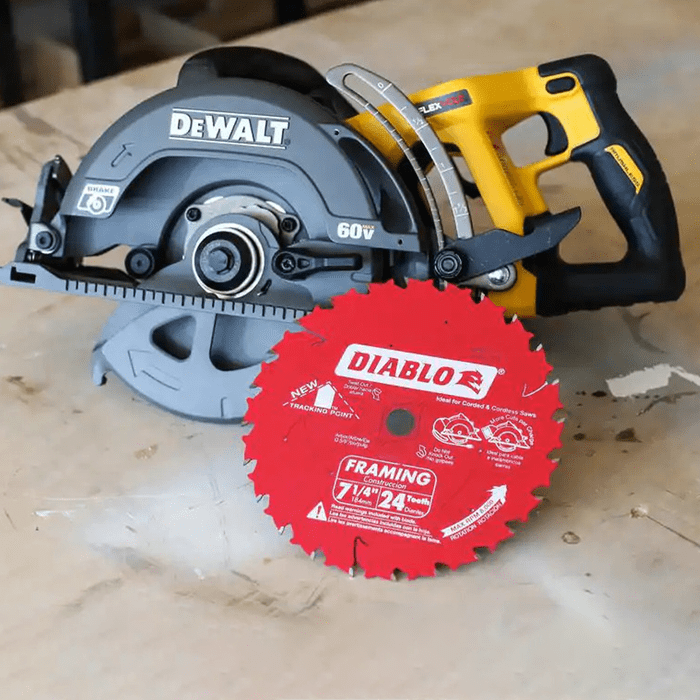

When tackling serious DIY projects, you need to make quick and accurate cuts in a variety of materials. Most require a circular saw blade for quick, easy crosscuts (across the grain) and rip cuts (with the grain). Circular saw blades are essential in any DIYer’s toolkit.

Although they’re typically used in handheld circular saws, they work in miter and table saws as well. Circular saw blades can cut hard and soft wood, metal and masonry. If you’re planning on cutting 2x4s, ripping plywood sheets, chopping up thin rebar or trimming concrete paving stones, you’ll need a circular saw blade.

Circular saw blades can be tough to tell apart, so keep these considerations in mind:

- Blade type: Identified by material. Whether you’re cutting wood, metal or masonry, make sure you choose a blade made for that specific use. Never use a masonry blade to cut wood.

- Size: Choose one that’s compatible with your saw type. Most handheld saws use 7-1/4-in. blades. Anything larger than that, up to 12 inches, will typically be best for a miter or table saw.

- Teeth: The number of teeth indicates which type of cut it’s best for. Blades with fewer teeth (18 to 30) cut faster and cost less than higher-toothed options; they’re ideal for making rip cuts in wood. Blades with a higher tooth count (60 to 80) are better for crosscuts in wood because they produce a smoother edge. Combination blades, with about 40 teeth, are good for crosscuts and rip cuts. If you’re not sure what kind of wood you’re cutting, go with a combination blade. Blades for cutting metal have various tooth counts, so make sure you know exactly what you’re cutting before you purchase one. Masonry blades lack teeth; these typically use a diamond blade to carve through brick and stone.

- Tooth angle: The angle affects the way the blade cuts. Teeth that lean forward, AKA positive-angle teeth, cut more aggressively and are good for rough rip cuts. The less aggressive the angle, the better the blade for clean crosscuts.

- Kerf: This the width of the blade’s teeth; it indicates how much material will be removed with each cut. Thinner kerf blades naturally require less energy to use, making them preferred for cordless saws with limited battery run time.

- Coating: We recommend a blade with a non-stick or protective finish, if you can afford it. This coating helps reduce the buildup of pitch, a natural residue from wood, that can create unnecessary friction on your blade. This friction can make the blade overheat and break down quicker.

- Sharpening: The relatively low price of circular saw blades makes them less practical to sharpen. Sharpening can cost more than buying a new blade. Once blades become too dull to cut effectively, they can be recycled at any recycling center or scrap metal dealer.

Article source here: The Best Circular Saw Blades for Your Home Workshop

No comments:

Post a Comment