Repair One: Weather Seal Your Garage Door Bottom Seal

If you want to keep the heat in your garage this winter or retain the cooled air next summer, you’ll have to do more than just install an insulated door. Most of the conditioned air escapes around and through all the cracks. Here are four simple ways to seal your garage door as much as possible. You can do the whole garage door bottom panel replacement job in an afternoon for as little as $100, depending on the size of the door.

Measure the Garage Door for the Seal

Start by measuring the width, height and thickness of your garage door. You’ll need those measurements to buy garage door stop with a built-in sealing lip and a new garage door bottom seal. While you’re at the home center, buy V-strip weather stripping, a tube of exterior caulk and a small can of wood sealer (if you have a wooden door). And for extra sealing power, buy a rubber threshold.

Some garage doors come with a metal track that holds a replaceable rubber seal. Over time, the seal flattens and cracks. If that’s what you have, replace it with a “cold weather” silicone-type seal, which remains flexible in cold weather and lasts longer. Lubricate the silicone seal with dishwashing detergent and slide it into the track slots.

Remove the Old Garage Door Bottom Seal

Lift the door just enough that the garage door track doesn’t get in the way of the weather seal, then slide out the old rubber bulb (Photo 1). You may need to pry the track ends open with a flat screwdriver if they’ve been crimped. If it’s especially stubborn, cut it and remove it in pieces.

Clean the door bottom (Photo 2), then cut the new rubber seal to length with a razor knife. Thread the T-shaped edges into the weather seal track, then slide the seal across the door. Be patient—it takes a lot of pushing and pulling even with a helper.

If you have a wooden garage door, rip off the nailed rubber seal. Then seal the wood with wood sealer. While the sealer dries, prepare the new aluminum track by cutting it to length and notching the ends so it fits around the bottom roller. Next, lay down a thick bead of caulk along the leading edge of the door and attach the track setup (Photo 4).

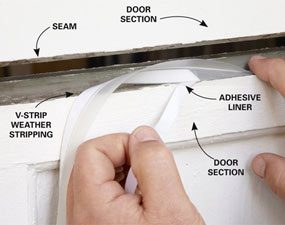

Prepare the areas between the door sections by cleaning them with a rag and household cleaner (be careful not to pinch any fingers). Then install the pressure-sensitive V-strip weather stripping (Photo 5). Repeat for each section.

Install the Threshold

Now move on to the threshold. Start by cleaning the concrete with degreaser and water. Rinse and let dry. Then roll the threshold into place with the hump on the inside of the garage door and cut to the width of the opening. Gently close the door onto the threshold and square up the hump to meet the door seal. Mark the edge of the threshold on the floor at each end and snap a chalk line along your marks. Next, glue the threshold into place. Close the door firmly against the threshold and leave it closed until the adhesive dries (Photo 6).

Install the Stop

Pry off the old door stop and install new door stop that has a sealing lip (Photo 7). Plus, these are the things to know before buying a garage door.

Seal a Garage Door Gap, Part Two

Here’s how to deal with gaps caused by an uneven bottom door panel or sunken concrete.

The easiest, but least elegant, method is to install several pieces of bottom seal retainer and rubber gasket in the gap areas. Just measure the thickness of your bottom panel and buy sections of seal retainer and gasket from a garage parts supplier. Mount the retainer to the bottom panel wherever there’s a gap. Finish the job by sealing the top edge of the retainer with caulk and then paint to match the door. This fix works on wood and metal doors.

If you have a wood door and want a cleaner look, remove the existing bottom seal and scribe/cut the bottom panel to match the contour of the concrete floor. Seal the freshly cut wood with wood sealer. Then remount the bottom seal.

Repair Two: Replace Rotting Garage Door Trim

Wood garage door jambs and trim often rot near the bottom or get crunched by bumpers.

A good, long-lasting solution is to replace the wood jamb, brick mold trim and doorstop with paintable solid vinyl pieces that won’t crack or decay. The vinyl can be cut, nailed and painted just like wood. It’s available in white, but you can order brown, bronze and tan. Fill nail holes with white caulk or exterior wood filler, then if desired prime and paint with acrylic latex. Use a light paint color over white vinyl to keep it from overheating.

Remove the old jamb and trim (Photo 1), then nail the vinyl jamb to the frame, beginning with the top piece (Photo 2). Fasten every 12 to 16 in. with 8d galvanized nails or stainless steel trim screws. Precut the miters on the top piece of brick mold trim and nail it to the framing every 12 inches with 10d galvanized casing nails. Use 6d casing nails for the stop molding, nailing it at the pre-marked points on the trim.

If the temperature is below 40 degrees Fahrenheit during installation, pre-drill nail holes and leave a 1/8-in. gap at the ends of the jamb for expansion.

Glue the brick mold corners with PVC cement (Photo 3), then nail them into place after the glue sets. To avoid breaking the joint, wait at least an hour for the glue to fully cure before nailing within a foot of the corner. Splice long runs with glued butt joints.

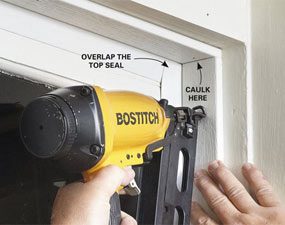

The edge of the vinyl stop molding should be 2-1/2 in. back from the garage door so the rubber seal fits loosely against the door (Photo 4).

Repair Three: Clean up a Rusty Door Track

Garage door tracks often rest directly on damp concrete floors, where they eventually rust. However, there’s no reason they can’t be slightly above the floor and stay dry: The garage rafters carry the weight of the track and the angle brackets hold the track in place.

Clean up the tracks and prevent rusting by simply cutting off the bottom 1/2 in. First make sure all the angle bracket bolts are tight, then cut the track bottoms off (Photo 1). Use a rag dipped in thinner to remove any lubricant on the first 6 in. of track, then scrape and brush off as much rust as you can. Finally, paint the bottom with a metal spray paint that’s formulated to bond to rusted areas (Photo 2). Rust-Oleum Rust Reformer is one choice.

Required Tools for this Garage Door Weather Stripping Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration. [project-tools]

Required Materials for this Garage Door Weather Stripping Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list. [project-materials]

Article source here: How to Winterize Your Garage Door

No comments:

Post a Comment