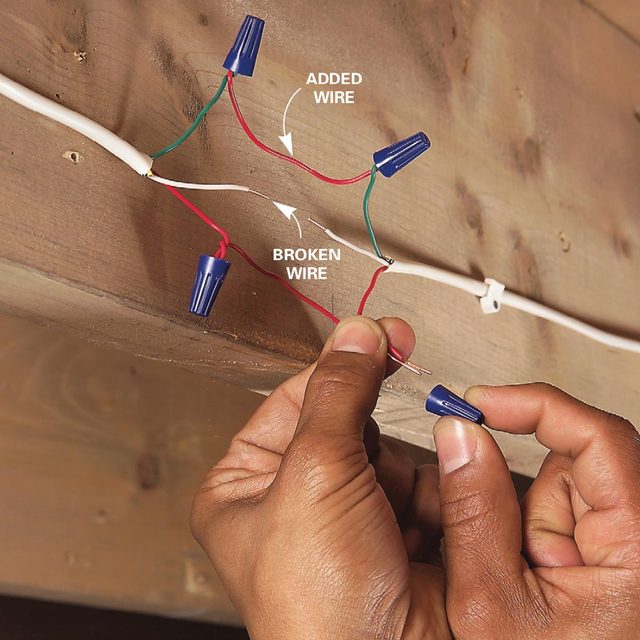

Inspect the Wiring

Inspect the wires for damage. Repair breaks with twist-on connectors. Splice in new wire to add length and allow for connections.

A complete inspection of doorbell wiring is usually impossible, since most of the wire is hidden inside walls. But some wire is visible in every home, and that’s usually the stuff that gets jolted loose or broken. An inspection takes only a minute. You may find a few inches of wire exposed near the transformer or several yards running through an unfinished basement. Doorbell cable consists of three or more thin wires inside a plastic sheath (Photo 1). Look for areas where the sheath is damaged, and also for pinched or badly kinked sections. Sometimes the only way to tell for certain whether wires inside the sheath are damaged is to carefully slice open the sheath with a utility knife. If you find broken wire, strip the broken ends and rejoin them with wire connectors. Often there’s not enough slack in the wire to allow for new connections. In that case, add a short section of wire between the broken ends. A spool of 18-gauge wire is available at hardware stores and home centers. The color of the wire doesn’t matter.

Clue!

If you have hardwired doorbell buttons at the front and back of your house and one of them works, you can be sure that the non-working button or the wiring connected to it is bad.

Adding a Second Doorbell Chime

Article source here: Repair a Doorbell: Fix a Dead or Broken Doorbell

No comments:

Post a Comment