Tired of scraping and repainting your trim? Or disheartened when you find that your trim has rotted and will no longer hold paint? Then step back and consider the advantages of replacing those problem boards with PVC azek trim—your worries will be over.

Cellular PVC board (polyvinyl chloride) azek trim is a close cousin of the familiar white plastic plumbing pipes. (The “cellular” part just means it’s filled with zillions of tiny air bubbles to make the material lighter and less expensive to manufacture.) But unlike its cousin, PVC azek trim is specially formulated to make it resistant to sunlight, hold paint well and easy to work with.

PVC azek trim looks just like wood (well, flawless wood) and lasts virtually forever. PVC azek trim impervious to rot and insect attack and doesn’t absorb water. It holds paint well because water can’t penetrate the material behind the paint. And if you like the look of white trim, you may not have to paint it at all (more on this later). It’s an especially good substitute for wood trim in areas that are highly exposed to water, such as corner trim boards and door trim that’s near the ground or unprotected by an overhang.

Although you install cellular PVC azek trim almost like wood, there are a few crucial differences. In this story, we’ll show you those special cutting, joining and fastening techniques so your PVC azek trim will perform flawlessly for the life of your home. Don’t worry—there aren’t any fancy tools or skills required. If you’ve cut and installed wood trim before, you have the moxie to work with PVC trim boards.

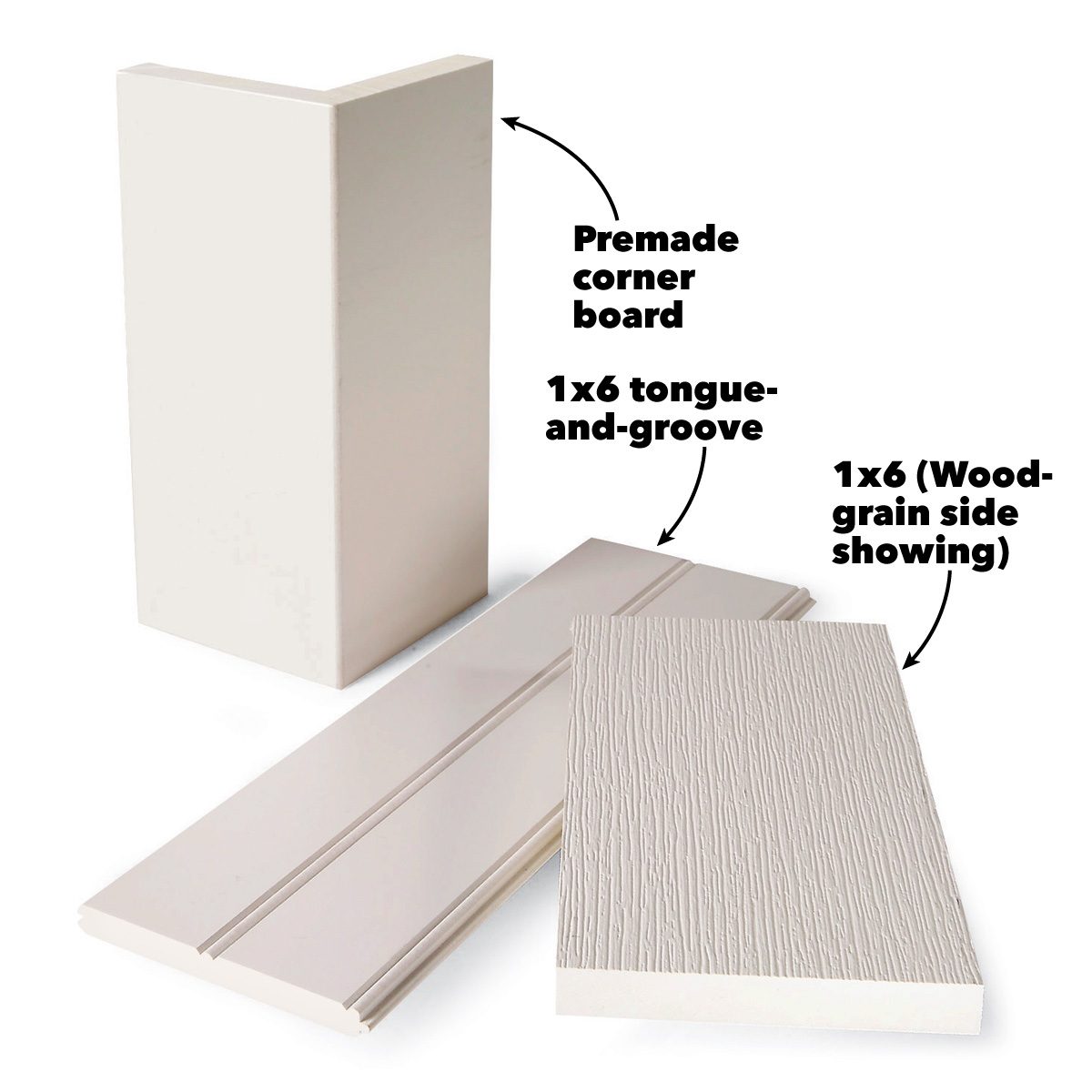

PVC trim is sold in 5/4 (1-in.) and 4/4 (3/4-in.) thicknesses in the common widths found with wood. But the selection may be limited. You’ll probably have to special-order some thicknesses and widths. PVC trim boards are sometimes only sold in 18-ft. lengths, so you may want to have your order delivered. Most companies offer material that has an embossed wood grain side and a smooth side, so you can choose the look you want. Don’t confuse cellular vinyl trim with polyurethane-core, vinyl-coated products. While they too are highly durable low-maintenance products, their installation techniques are different.

PVC trim isn’t cheap; expect to pay about the same price you’d pay for clear, knot-free wood. Other PVC products are also available, including preformed outside corners, tongue-and-groove boards, and sheet goods that you can carve up and work just like plywood.

Find PVC trim by contacting lumberyards in your area.

Cut with carbide-tipped saw blades and bits

Cut PVC trim boards with the same hand and power tools that you use for wood. But use only carbide-tipped saw blades; plain steel ones will dull quickly. In general, the more teeth a blade has, the smoother the cut edges will be. We recommend standard combination saw blades. You can easily rout decorative edges or grooves with routers or shapers, but use carbide-edged bits as well.

Sawn edges aren’t as easy to sand as wood. So if possible, plan your work so that newly cut edges will butt against siding, soffits or other trim, and let the smoother factory edge show wherever possible. Sanding isn’t always necessary, especially if you plan to paint. But sand exposed edges that are highly visible, like near the front door. Use a random orbital sander with 100-grit paper. Belt sanding doesn’t work well because the friction from the belt melts the plastic rather than smoothing it.

Article source here: Cutting and Installing Plastic Trim

No comments:

Post a Comment