Tip 1: Fill wide gaps with setting compound-it hardens quickly and won’t shrink

Regular drywall compound shrinks too much to be used for wide gaps and voids (Photos 2 and 3). And it takes days to dry. Setting compounds, on the other hand, harden quickly and hardly shrink at all. And you can apply your tape coat as soon as they harden. No waiting. You buy setting compounds powdered in sacks (photo 4). Mix them with water in your mud pan to a paste consistency, about the same as regular compound, and press them into gaps, especially those wider than about 1/4 in. Keep the fill level even with, or slightly below, the surrounding surface. Work quickly, because the water activates a catalyst that causes the compound to harden. Setting times vary, depending upon which mix you buy. Start with a 90- minute setting compound to give yourself plenty of working time so it doesn’t harden in your pan (See Tip 4).

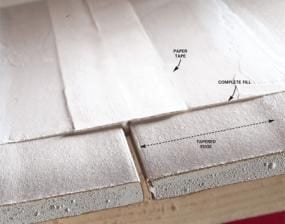

Tip 2: Completely fill tapered joints with setting compound

Tapered drywall joints have special edges that provide a pocket for joint compound and tape. They’re deceptively easy to fill because there’s plenty of space for both tape and “mud.” However, the trick here is to completely fill the joint, flush with the surrounding surface, on your first coat. If you tape with a setting compound, it’ll hardly shrink, so the joint won’t need further filling (Photo 1). That eliminates the need for deft knife work later to make all the surfaces even. You can concentrate on smoothness during the next two coats.

Scoop up a large lump of compound and lay it in quickly, completely filling the tapers (Photo 2). Lay on the paper tape and lightly smooth it into the mud with your knife (Photo 3).Finally, spread a thin coat of mud over the top of the tape. Make light strokes with your knife. Pressing too hard will flex the blade and depress the compound, leaving you with more filling to do with the next coat.

Tip 3: Bridge from the tape to the wall for smooth inside corners

Inside corners are the easiest joints to tape smoothly. The key is to rest one end of your knife blade on the tape in the corner and the other on the drywall surface to create an even taper along each wall.

Begin by laying a ribbon of mud about 1/8 in. thick and 2 in. wide along each side of the corner (Photo 2). Then sharply crease the paper tape and tuck it into the corner. The crease stiffens the tape and helps keep the corner straight and crisp. Quickly and lightly stroke your knife over both sides of the tape to position it exactly in the corner. Then apply more pressure and use the tape on one side and the wall surface on the other as leveling guides to embed the tape smoothly and evenly. Some mud will squeeze out, but leaving about 1/16 in. under the tape will do. You can leave an irregular mud edge at this stage. It’s easy to fill and smooth during the second coat.

Tip: Hold your knife at a slight angle to the adjacent wall (not square to it) so you don’t gouge the mud on it.

Tip 4: Completely fill the corner bead pocket on outside corners

Setting compound is ideal for filling outside corners or other places where you use metal or plastic edge beads. Corner beads usually leave about a 1/8-in.mud pocket (Photo 1), which you want to completely fill in one coat. Lay on plenty of mud. Then simply drag your 6-in. knife along the bead on one side and the drywall on the other. Use light pressure; a heavy hand here will squeeze out the mud, leaving a hollow that’ll need more filling later.

The most common problems occur when the corner bead is misaligned, making the mud pockets too thin or too thick. To avoid this problem, always run your taping knife down each side of the corner bead to check the pockets before you apply compound. Readjust the corner bead if necessary.

Tip 5: Apply a thin coat of compound at butt joints

Butt joints, where two non-tapered edges meet, are the most difficult to hide because the tape sits above the surface of the drywall. The best advice is to avoid them like the plague! Use longer pieces of drywall if possible (10-ft. or 12-ft.) to span walls and ceilings. Unfortunately, you always end up with a few.

The secret of making a butt joint invisible is to keep your tape coat as thin as possible. Begin by cutting a shallow “V” along the edges (Photo 2). This removes any fuzzy, torn or loose paper; trims back crushed edges; and removes anything that might protrude and lift the tape. Slice with a sharp utility knife here.

Then apply about a 4-in. wide ribbon of mud about 1/8 in. thick over the joint (Photo 3). Make sure to completely fill the “V”. Lay on the tape and embed it with a light stroke of your knife, leaving no more than about 1/16 in. of mud under the tape (Photo 4). Be sure to apply a thin second layer of mud over the tape. Then lightly stroke down each side to taper the extra mud away from the center. Once the compound dries, taper the edges out a foot or more with later coats to hide the bump left by the tape.

Drywall Tape Repair

One common mistake is to press too hard and squeeze all the mud from under the tape. Then the tape will lift (bubble) when it dries. You can cut out occasional bubbles with a utility knife and remud. But if whole sections become loose, you have to scrape off the old tape and retape.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Mud pan

- Taping knife

- Utility knife

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- Drywall tape

- Setting-type joint compound

Article source here: Taping Drywall Tips: How to Tape Drywall Joints

No comments:

Post a Comment