Inspect 4×4 Lumber Before Buying:

If you need 4x4s or other large posts, inspect them first. Why? Many of them, especially 8-ft. posts, come from logs used for veneer, which is peeled from the logs like paper towels from a roll, leaving only the very center of the log. The center “pith” is the least stable part of the log and is very prone to twisting, splitting and bowing. This is particularly true of treated 4x4s because the treatment exaggerates the warping. Learn about wood movement 101.

Examine the stack of posts at the home center and reject the posts with end grain that looks like a bulls-eye. Choose the straightest posts you can find, with the least amount of center pith.

How to Get the Best of the Pile:

Look for posts without a “bulls-eye” and growth rings from edge to edge. Perfect is rare. Find the best you can. Plus, check out how to find the best home center lumber for your DIY projects.

How to Buy Rough-Sawn Lumber

Family Handyman

Family Handyman

Rough-Sawn Lumber Basics

If you're into

woodworking even a little bit, you should consider buying rough-sawn lumber for your next project. And rough-sawn is the only way to go if you need really thick boards. Plus, you can save yourself a ton of money converting roughhewn lumber to finished product; maybe enough to justify buying that planer you’ve always wanted. A lumberyard that specializes in rough cut lumber will have a much, much larger selection of species to choose from than a home center. But there are a few things you should know before heading to the yard. That’s why we took a field trip with a pro woodworker to a lumber yard in Minneapolis. He clued us in on which tools you should take along to the yard and how to estimate what size lumber to buy. He showed us what to look for and warned us what to avoid. These great tips will help you choose your rough cut lumber carefully and spend your money wisely.

![What's a Board Foot? What's a Board Foot?]()

What's a Board Foot?

Lumberyards sell rough-sawn wood by the board foot, not linear foot. A board foot (bd. ft.) is 144 cubic inches of wood. Bring a tape measure because the length and thickness of the boards might be labeled, but the width will not. Here’s how to figure out board feet:

Plus:

Making Sense of Lumber Dimensions

![Buy Extra Buy Extra]() Family Handyman

Family Handyman

Buy Extra

Picking out and hauling home rough-sawn lumber and then milling it into usable boards is time-consuming, so buy extra. You don’t want to go through the whole process to mill one board to replace one that gets damaged. Also, the color and grain of the new board may not match the boards you bought on your first trip. Buying and milling at least one extra full board is a good idea. Plus:

Planing Rough-Sawn Lumber with a Jointer and Planer

![Go Long Go Long]() Family Handyman

Family Handyman

Go Long

The ends of rough-sawn boards often contain checks (cracks). Some checks are obvious, but some you won’t discover until you cut the board near the end. So plan on discarding several inches on each end of every board. That means that if you need two finished 4-ft. boards for your project, buy a 10-ft. rough-sawn. Plus:

Repairing Wood: Strong Glue Joints in Wood

![Avoid Twists Avoid Twists]()

Avoid Twists

Steer clear of any board that looks like a banana, but minor warping can be removed in the milling process. The shorter the boards you need, the bigger the bend you can work with. However, avoid twisted boards. The internal forces that are causing the twist may never go away no matter how much material you remove. Our expert’s motto: “Once twisted, always twisted.” Plus:

Choosing 4x4 Wood

![Pick Thicker Boards Pick Thicker Boards]() Family Handyman

Family Handyman

Pick Thicker Boards

Hardwood lumberyards sell rough-sawn lumber in various thicknesses. Most yards label thicknesses in 1/4-in. fractions: 4/4 = 1 in., 5/4 = 1-1/4 in., 6/4 = 1-1/2 in., etc. Buy boards at least 1/4 in. thicker than your final dimension in order to account for the material that will be

removed by the jointer and planer. Thicker boards cost more per board foot, so you won’t save any money by buying a 2-in. board and resawing it into two 1-in. boards.

![Check the Color with Water Check the Color with Water]() Family Handyman

Family Handyman

Check the Color with Water

These days, most rough-sawn lumber receives one pass through a planer or sander on each side before it reaches the yard. The process, called hit-and-miss, usually smooths the surface enough to see the character of the grain you’re dealing with. But two similar-colored boards in the same bin may differ dramatically in color when finished with a clear topcoat. If it’s important that all your boards be close to the same color, take along a spray bottle filled with water. A couple quick squirts should expose any surprises. Plus:

Finishing Wood Trim With Stain and Varnish

![Watch Out for Sticker Stains Watch Out for Sticker Stains]()

Watch Out for Sticker Stains

Stickers are the spacers used to separate boards while they’re drying. Occasionally stickers can create shadow-like stains. These stains appear to be just on the surface, but it’s common that they go deeper than 1/8 in. into the wood, so they may still be visible after planing. Plus:

How to Stain Wood Evenly Without Getting Blotches and Dark Spots

![Use Lower-Grade Lumber and Save Use Lower-Grade Lumber and Save]()

Use Lower-Grade Lumber and Save

Lumber with more knots costs less, which makes sense. If your project contains a bunch of smaller pieces, you can save money by cutting out and around those defects. This lower-grade lumber is often called No. 1 Common (1C). Sometimes you can find a gem or two that may look good enough as is, or have long enough clear cuts between the knots for the boards you need. Plus:

Understanding Plywood Grades

![Save Money on Rough-Sawn Save Money on Rough-Sawn]()

Save Money on Rough-Sawn

Buying rough-sawn lumber and

planing your own wood definitely saves money; how much money depends on the species and on the size of the project. The larger the project, the more you save.

![Old Boards Need Cleaning Old Boards Need Cleaning]() Family Handyman

Family Handyman

Old Boards Need Cleaning

Dirty boards will dull planer and jointer blades. If it looks like your prize board may have been kicking around the yard for quite a while, plan on scouring it with a wire brush before milling.

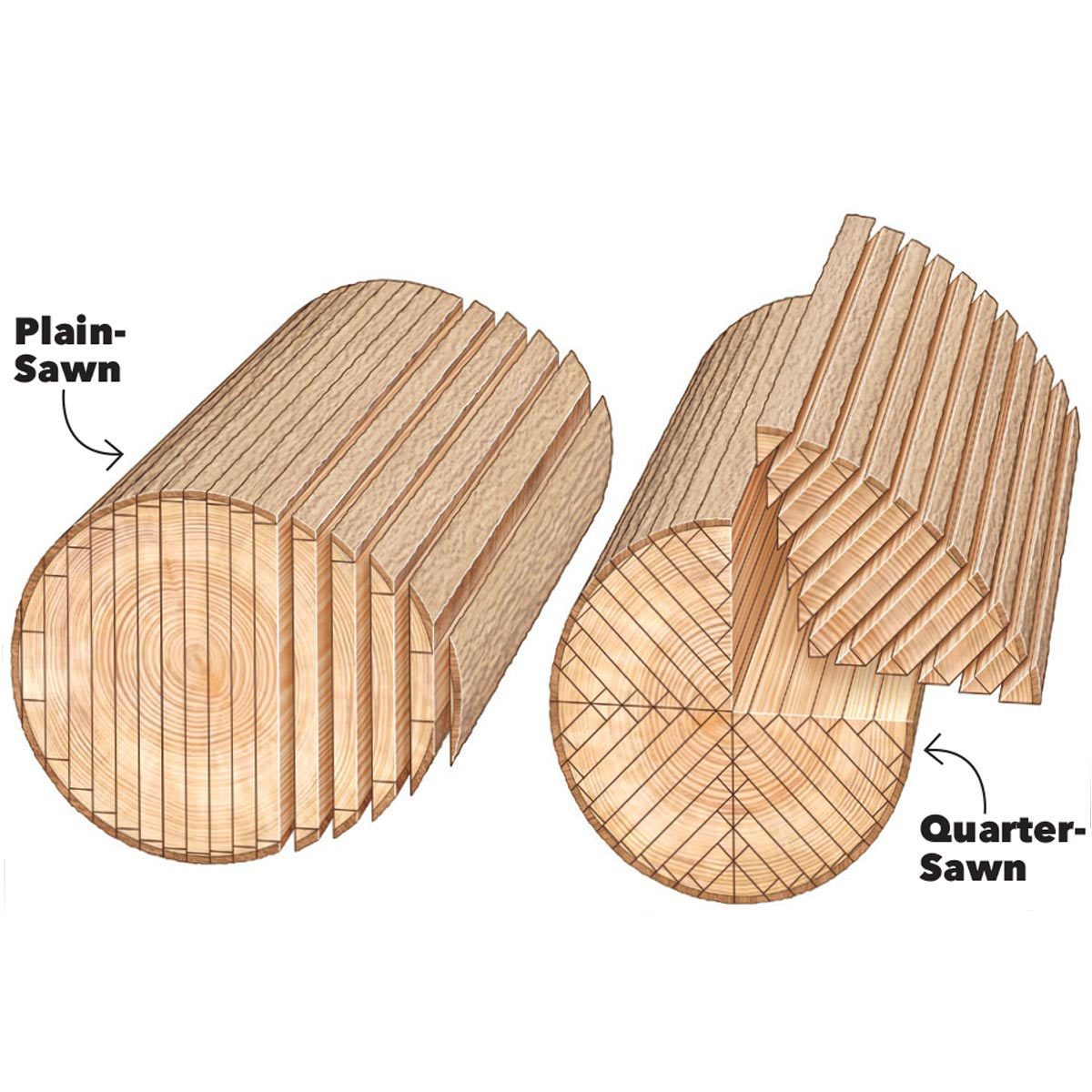

![Plain- vs. Quarter-Sawn Plain- vs. Quarter-Sawn]()

Plain- vs. Quarter-Sawn

Most rough-sawn wood these days has been plain (or flat) sawn. But you may come across a couple of species that have been quarter-sawn. Quarter-sawn wood is more stable and much less likely to warp, but it also costs a lot more. Plus:

How to Use a Bench-Top Planer

![Take a Saw Take a Saw]() Family Handyman

Family Handyman

Take a Saw

Your perfect board may be 12 ft. long, which isn't likely to fit in the back of your Ford Fiesta.

Take along a saw to cut long boards into manageable lengths. Pay for the boards before you cut them down.

![Beware Super-Wide Boards Beware Super-Wide Boards]() Family Handyman

Family Handyman

Beware Super-Wide Boards

You may come across a

gorgeous slab that’s wide enough for a tabletop. But building with wide boards is risky. If they’re cut too near the center of the tree, they can cup dramatically. To guarantee a flat surface, you’re better off gluing up boards that are 5 to 7 in. wide than ones that are 12 in. plus. Also, really wide boards may not fit in your planer.

![Don’t Have a Jointer? Don’t Have a Jointer?]() Family Handyman

Family Handyman

Don’t Have a Jointer?

Many yards will “straight-line” one edge for you so that you can rip the boards to the desired width on your table saw. Some can plane boards down in thickness, too, but there’s no guarantee they’ll come out flat. Plus:

Our Favorite Woodworkers Tools

![Buy Local Buy Local]() Family Handyman

Family Handyman

Buy Local

There may not be a commercial hardwood lumberyard near you, but it’s likely that someone in your area has a small sawmill and sells various local species. Your state’s DNR website might have a listing of these smaller sawmills. Hiring someone with a portable sawmill is a good option if you want to saw up wood harvested from your own property and are willing to go through the lengthy drying process. Invest $30 in a moisture meter before buying rough-sawn lumber that has been air-dried. Check that the moisture level is between 12 and 15 percent before loading up your truck. And when you get your air-dried boards home, store them inside to dry them even further. Ideal moisture content is about 6 to 8 percent. The lumber you buy at a commercial yard should have been kiln-dried. Plus:

DIY Space Saving Wood Trim Drying Rack

![Buy Online Buy Online]() Family Handyman

Family Handyman

Buy Online

A lot of furniture builders buy cheap, rough-sawn wood online, especially when working with hard-to-get exotic woods, extra-wide boards or boards with a live edge (bark still on). Shipping will be expensive and returns may not be an option, so make sure you see a photo of the exact boards you’re buying. The best suppliers will have photos on their website. Plus:

Wood Finishing Tips

Article source here:

Why You Should Be Careful When Selecting 4×4 Lumber

Family Handyman

Family Handyman

Plus: Making Sense of Lumber Dimensions

Plus: Making Sense of Lumber Dimensions Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

Family Handyman

No comments:

Post a Comment